Closed Door Cabin Blaster Layouts.

- Silvio Ruiu

- 4 days ago

- 5 min read

Updated: 7 hours ago

All these equipment work "by batches", parts are placed inside, processed and then removed, kinda "washing machine" concept, there is always one door or more to enclose the blasting room. Here is the overview how it works.

Cycle timing is one of the crucial settings.

Summary of Cabins type layouts:

Tableblaster - mono wheel ⬇️ here below.

⬆️Table blaster – one blastwheel.

Where a rotating base, with parts on its top, is placed under the media jet.⬇️

Tableblaster media launch pattern on the rotating table.

Pros: easy to use and compact, open cabin allows quick inspections, coverage extremely consistent in combo with planetaries in “2d”.

Cons: bottom of parts lying not blasted, in case needed it requires flipping, it works great on a “flat” not on 3d volume, if parts have “3d” shape requires longest cycles. Load/unload not so easy to be automated. Parts may fall below the table.

Booster: two carts with sliding in/out frame allow to move parts around while blasting cycle is ongoing.

Common applications: tools cleaning, like glass molds, extrusion dies, tires molds and any other "shaping tool", specific roughness surface preparation, shotpeening.

⬆️Table blaster – 2 (or more) wheels.

The eight of equipment rises, wheels are still on the side, one blast from top one from bottom for perfect coverage.⬇️

Pros: parts are usually hanged to a fixture, so it can give a perfect 3d coverage’ specially in combo with planetaries, easy cabin to inspect, can cut cycle time by 60/70% from the single wheel if flipping is needed; as well almost same footprint.

Cons: more expensive due to double controls and higher capacity accessories for the double quantity media to handle.

Booster: two carts with sliding in/out frame allow to move parts around while blasting cycle is ongoing.

Common applications: vertical extrusion dies cleaning, descaling after heat treat, nitriding cleaning, pretreatment before electrochemical finishings like nickel plating, deburring, investment casting, specific roughness surface preparation, shotpeening.

⬆️Tumbleblaster – Rubber belt.

A rotating belt mixes continuously the parts providing the tumble effect:

While the media jet is coming from the top of the cabin, parts also protect the belt itself from the media flow abrasive action. It works on the ratio between volume/weight of the parts tumbled and blasted. Sizes of these cabin may vary a lot, so it goes wheels number and automations to load/unload. Here below, smaller or bigger doesn't matter, the media pattern on this cabin. ⬇️

Pros: if the combo effect of tumbling and blasting is accepted by the parts, production can be incredibly high, automation on load/unload can create a perfect workstation that almost doesn't require any human intervention. Cabin inspection easy on manual loaded machines.

Cons: Less versatile than a table blaster, the belt is a part of the machine that needs to be customized accordingly with parts and media used; replacing it may take sometime and efforts.

Booster: automation can easily turn a timbleblaster in a self sufficient workstastion capable of very high mass production rate.

Common applications: 3d printing, descaling, shotpeening, deburring, investment castings.

Tumbleblaster - steel belt.

It is valid all the above for the rubber belt, the extra is about the belt made by steel slats (or strips), it is used for heavy applications. Specs are here. These equipment are generally extremely customized so going into general meaning does not make any sense.

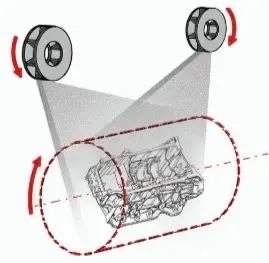

⬆️Monorail - Hanger Cabinet.

All machines with a rail on top, to guide parts in & out, automation level can be settled to different stages and easily automated also for load/unload with robot or similar devices, eventually the can be installed in a pass thru line advancing by steps and not continuosly. Media pattern is here below and number of wheels goes with the height of the cabin itself. ⬇️

Pros: really good coverage beacuse the hanger is rotatong and oscillating too, cabin easy to inspect, easy automation for load/unload, some railways allow the connections to previous steps (i.e. heat treat) or further steps.

Cons: to be fully optimized requires a load/unload system, the manual work may be massive.

Booster: to use the same batch for the entire production and hang an entire fixture or installing cranes to optimize the lifting of voluminous heavy loads.

Common applications: descaling after heat treat, nitriding cleaning, pretreatment before electrochemical finishings like nickel plating, deburring, investment casting, specific roughness surface preparation, shotpeening.

⬆️Monorail - Tableblaster combined.

Practical combination to handle hanged parts and occasioanlly the big heavy parts on the high capacity main table. Media pattern like the cabin above.

Pros: practicality, can be loaded both ways and handle plenty of tasks. Easy to check cabinet wear.

Cons: versatility has a cost in terms of Capex due to the more complicated building, also more wear parts while in operations. Eventualy parts lying on the main table needs to be flipped if bottom side should be blasted as well.

Boosters: carts to load the table, crane for the hooks.

Common applications: descaling after heat treat, nitriding cleaning, pretreatment before electrochemical finishings like nickel plating, deburring, investment casting, specific roughness surface preparation, shotpeening, general castings.

⬆️CM S60H Automated Arm Blaster - Patented.

Central arm comes in an out, can be fed by a robot or a rolling table, incredible high productivity for deburring process after low pressure castings and similar applications. Here below is the media pattern.⬇️

Pros: high automation and high productivity, run about 1 part per minute with low pressure aluminum casting. Extremely easy maintenance.

Cons: the arm must be designed accordognly with the parts to process, in case of "big" format change needs to be redesigned and changed.

Booster: modern protocol allows to contrl the full machine remotely, allowing to integrate it in a workstation fully automatic.

Common applications: aluminum low pressure casting for automotive and not only automotive.

General blaster components summary:

Wheel blaster, how is made. general overview

Closed blaster cabinets. layouts of most common equipment running on cycle time - this post.

Open blaster cabinets. layouts of most common equipment running on cycle time.

Wheel Blaster Elevator. how it works and how to fix common issues.

Media Washer. How it works and how to set it up.

Blaster Filter house. How it works and common issues.

Blaster Control panel. How to keep it efficient and long lasting.

Blaster accessories and ancillaries. How simple items can improve quality.

Media, the fuel of the blaster. General overview and features of media types.