Blaster Control Panel Specs.

- Silvio Ruiu

- 1 day ago

- 2 min read

Updated: 7 hours ago

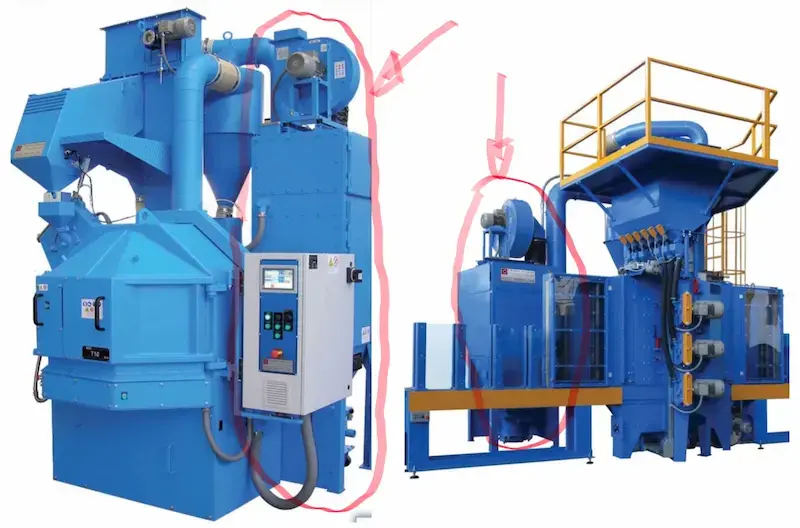

Control panel is where the major eclectronics are located, it is often placed on the side of the cabinet or it is a standing box, see below⬇️:

Control Panel Protection.

If speaking about an equipment 15 years old or newer, probably sounds surprising that the control panel bill is almost half of the full pricetag of the whole machine considering the hardware and software there inside; it is a must to keep its door(s) closed and to keep its AC unit working - clean the filters once in a while - to get an increase of the lasting of all components. And this is crucial.

Inside blaster control panel history.

It is possible to identify 3 stages:

Until late 90's, all inside was electromechanical, anything was broken could be replaced by parts sourced locally with the same features, set and keep the machine working.

Late 90's - 2015, electronics entered the game, more flexibility still each item disconnected from the others, a broken part can be replaced - if found - strictly with the same item by just uploading the software.

2015 - today, many components are connected by network, so you need the same part, make sure firmwares are compatible, allocate the IP address and load the software to make it working properly. Simple plug & play is just a memory without the software job behind done.

We got flexibility and remote control, it doesn't came for free.

Today status.

Components process an incredible quantity of data, generate heat so the ventilation holes are big requiring an AC unit to cool down, sealed cabinet to live in a dust free environment. Safety has been increased a lot enforced by norms and regulations, from the pure company liability point of view using an equipment older than 10 years means exposing to high risk.

Would consider beneficial a review to any control panel older than 10 years, to understand what is available - and how long does it take - on the market, eventually evaluating a retrofit for the existing control panel to avoid future massive unexpected yet expensive downtimes.

Conclusion.

Obsolescence is a real thing, the only possible way to skip all the related issues is to predictively approach the subject instead of being passive waiting the disaster, creating a proper protocol to avoid and eventually react to any issue may occur.

General blaster components summary:

Wheel blaster, how is made. general overview

Closed blaster cabinets. layouts of most common equipment running on cycle time.

Open blaster cabinets. layouts of most common equipment running on cycle time.

Wheel Blaster Elevator. how it works and how to fix common issues.

Media Washer. How it works and how to set it up.

Blaster Filter house. How it works and common issues.

Blaster Control panel. How to keep it efficient and long lasting - this post.

Blaster accessories and ancillaries. How simple items can improve quality.

Media, the fuel of the blaster. General overview and features of media types.