Wheel Blaster Filter, how it Works.

- Silvio Ruiu

- 1 day ago

- 6 min read

Updated: 7 hours ago

Filter (or dust collector) is critical part of the blaster, it provides the suction inside the blasting cabinet and the washer, also handles the dust, storing it SAFELY. For references you can read the general about how wheel blaster is made and works here. [link all'introduzione]

⚠️Disclaimer⚠️:

Residual blasting/peening dusts may be potentially flammable, explosive in confined space, follow carefully equipment manual, operations must be performed accordingly.

As already clearly stated above, safety is everything on this device, it is obvious for anyone attending the production floor, so is for the Managers in terms of legal resposibility which is easily to understand turns into company/corporate liability.

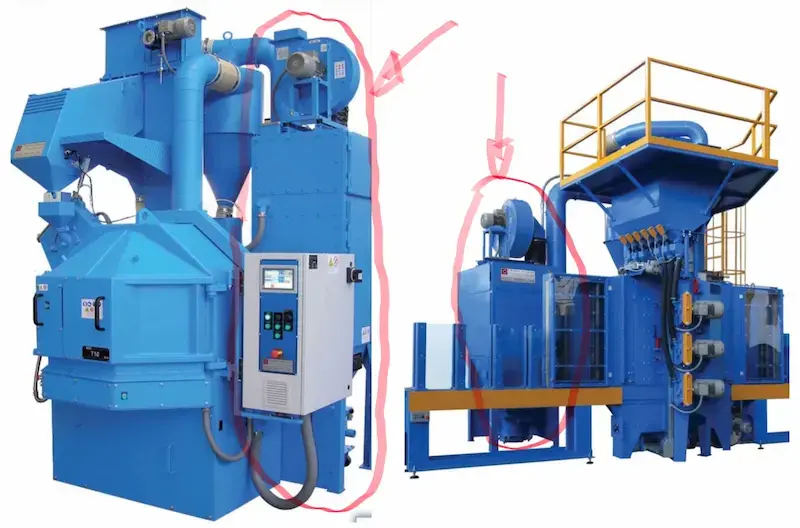

Blaster Filter external appearance.

In general is a tall metal box with a fan on top placed on the side of of the blasting room, or connected to by pipe of consistent diameter if placed somewhere else for safety reasons, like shown here below⬇️:

Looking from top to bottom it is possible to identify few different areas:

Extraction Fan & Motor: Responsible for the airflow. It MUST be certified/labeled for hazardous explosive environments (ATEX/UL-FM).

Clean Air Chamber: Where the pulse-jet air tanks are located. This area must remain dust-free, if not check here.

Filtering Chamber: High-risk area containing the cartridges. Cartridges must be antistatic/conductive and properly grounded.

Explosion Vent (Anti-explosion panel): A safety membrane designed to rupture if pressure rises too fast (typically set at 1 bar / 14.5 psi). It features a chimney to divert gases upward, protecting personnel.

Dust Collection Hopper/Bin: Where dust is stored. Think of this as a "fuel tank" open to the environment: the less dust inside, the safer the plant. ALWAYS ensure the bin is grounded after emptying.

Very old filters may still use sleeves instead of cartridges, if you have one of those reach out here to get support or to evaluate a retrofit. Summarizing it is normal to refer to the wheel blaster as equipment, becuase is literally made by two machines, the blaster (with its items to make it working) and the filter house, which is another machine. If you drive a car relatively brand new, with engine issues due to whatsoever reasons, you may think to buy and replace the whole engine to get back close to the initial efficiency; in the end you will drive the same car with major issued fixed. I'm not saying replacing the dust collector is a "standard" intervention, indeed it is a way to optimize safety, increase efficiency and solve the liabilities issues; upgrading part of the equipment where it counts, it is the definition of "value for money.

Blaster filter how it works inside.

The fan on top provide the suction, air is aspired from by the pipe connecting the box to the blaster - usually thru the cyclone; when it arrives into the box is filtered by the cartridges and then it goes out thru the fan. If cleanliness of the environment inside the building is critically important a gateway outside of the building is mandatory.

Dust falls into the bin located at the bottom from the cartridges, to keep them efficient a pulse jet air system is installed, quality of the compressed air is important, humidity free and oil free is a must. Fan speed is adjusted by a drive to compensate for the Delta P (pressure drop): it slows down when cartridges are clean and speeds up as they get dirty to maintain constant suction. If the Delta P stays high after cleaning, your cartridges are "blinded"—they are dead.

It is impossible to forecast in advance how long cartridges will last, if the environment inside the building is clean duration can reach even more than 5 years and thousands of blasting hours, if it's dusty they can be critical in 6 months and 500 hours only.

Filter Norms and guidelines.

Leading norms are provided by EU and US, beside different names and categorization the approach is the same: classifiying the zones of the equipment and surroundings areas by the hazardous factor connected with concentration of dust due to the machine itself and the environment. A spark source is not dangerous by itself, so is a bowl of petrol; until those two items are far enough to not influence each other, if them are close the game changes and disaster may be just a step away.

Summarizing:

ATEX (EU) vs. NEC (USA) Comparison Table.

Concept | ATEX (Europe) | NEC (USA) |

Combustible Material | Gas (G) / Dust (D) | Class I (Gas) / Class II (Dust) |

High/Medium Risk | Zone 0 / 1 or 20 / 21 | Division 1 |

Low/Occasional Risk | Zone 2 or 22 | Division 2 |

Filter norms for references:

Industrial Safety Standards in EU & US.

Scope | EU Standard (ATEX) | USA Standard (NFPA/OSHA) | Application in Blasting/Peening |

Manufacturer Requirements | Directive 2014/34/EU | UL / FM / ISA Standards | Engineering of motors, turbines, and sensors to prevent ignition. |

User/Employer Obligations | Directive 1999/92/EC | OSHA General Duty Clause | Risk assessment, housekeeping, and operator safety protocols. |

Combustible Dust (General) | EN 60079-10-2 | NFPA 652 | Fundamentals of identifying and managing dust explosion hazards (DHA). |

Combustible Metals (Al/Mg/Ti) | EN 16061 | NFPA 484 | Specific requirements for handling explosive metal dusts (Aluminum, Titanium). |

Explosion Protection Systems | EN 1127-1 | NFPA 68 / NFPA 69 | Design of explosion vents (rupture disks) and isolation valves. |

Electrical Installations | EN 60079-14 | NEC (NFPA 70) / NFPA 79 | Wiring, grounding, and enclosure ratings (NEMA vs. IP). |

Critical Differences

The Nature of the Norm: * In the EU, ATEX is a law (Directive).

If you don't follow it, you are breaking a specific statute.

In the USA, NFPA standards are "consensus standards." However, OSHA makes them de facto mandatory by citing them under the "General Duty Clause."

The "DHA" (Dust Hazard Analysis): Under NFPA 652, US companies are strictly required to have a written DHA for their processes.

Companies in the US without a DHA are in a state of high liability.

Grounding & Bonding: * While both systems require it, NFPA 484 is extremely prescriptive about the daily testing of grounding for metal dust containers.

This brief summary is NOT exhaustive, once again it is true the way of saying "safety is everybody job", for the workers to back home safely when their shift is over; for Mangers due to the high liability connected with it.

If you need to review your filter status it is possible to start here.

Troubleshooting common filter issues and DIY* checks.

Whistling from the fan, it may be related to a pad of the the fan not properly fixed, vibration may be the cause; fan house has inspection window, it must be opened and check if all the bolts/nuts are securely fastened.

Dust in the clean air chamber, may be related to a broken cartridge or not perfect installing of it, verify the related gasket and eventually repair/reinstall/replace accordingly.

Dust on the machine, look for the source, check all the gaskets and junctions, on the filter and on the cabin.

HMI reporting not enough suction, check the inspection doors, check instruments, check if the bin at the bottom is securely firmed. AND GROUNDED.

*DIY - it is related to skilled and experienced maintenance people, ask help to your maintenance team if you are not or just feel not comfortable about.

Hopefully you are all set, if you need extra support you can email at: silvioruiu@gmail.com.

General blaster components summary:

Wheel blaster, how is made. general overview

Closed blaster cabinets. layouts of most common equipment running on cycle time.

Open blaster cabinets. layouts of most common equipment running on cycle time.

Wheel Blaster Elevator. how it works and how to fix common issues.

Media Washer. How it works and how to set it up.

Blaster Filter house. How it works and common issues - this post.

Blaster Control panel. How to keep it efficient and long lasting.

Blaster accessories and ancillaries. How simple items can improve quality.

Media, the fuel of the blaster. General overview and features of media types.